Prototyping is where vision meets reality — but too often, founders treat it like final product development. They pour in money, overcomplicate the design, or skip critical physical details, thinking software logic or renders are enough. The result? Delays, wasted resources, and failed tests that could’ve been prevented.

Here’s what startups often get wrong, and how to avoid the trap.

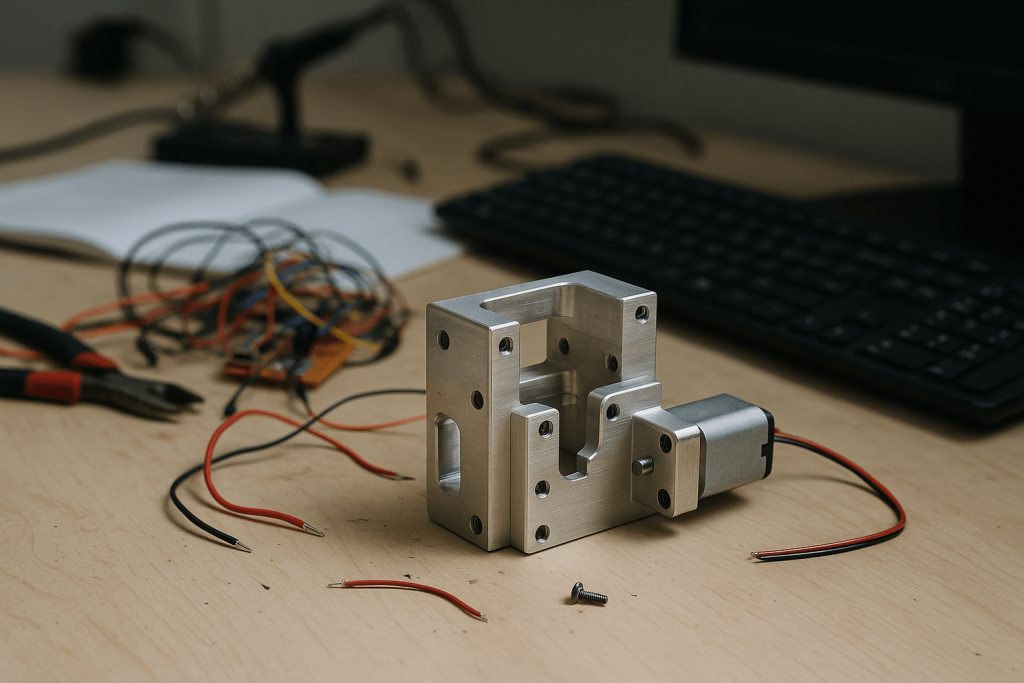

1. Over-Engineering the MVP

“We want it to be perfect from day one.”

Wrong mindset. Your MVP’s job is not to be final. It’s to test feasibility, raise eyebrows, and get feedback.

What goes wrong:

- Custom PCBs when an Arduino would do

- CNC-machined parts, when a 3D print proves the point

- Weeks lost waiting on “final” suppliers

Better move:

Use off-the-shelf components, simplify the housing, and focus on testing one core function, not everything.

2. Skipping the Mechanical Design

“It looks good in CAD — why wouldn’t it work?”

Because CAD doesn’t show tolerances, stress points, or what happens when things move.

What goes wrong:

- Hinges don’t close

- Parts don’t align

- Real-world friction and flex ruin the build

Better move:

Do quick-fit tests early. 3D print in draft mode. Validate the assembly physically before polishing.

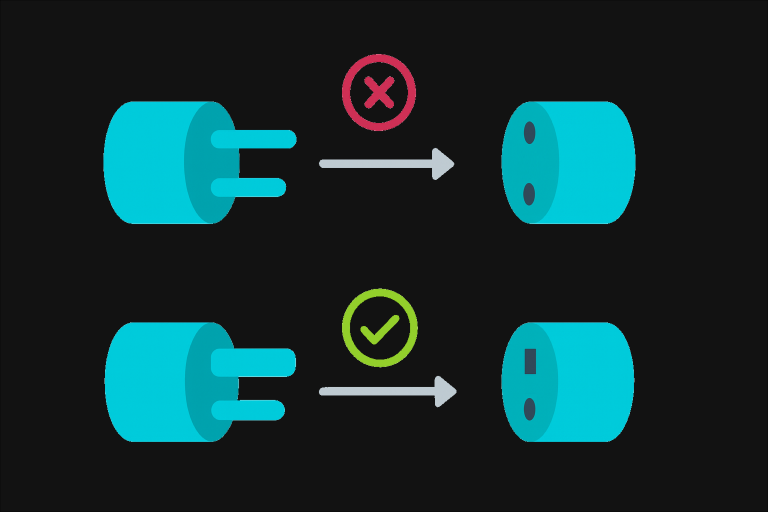

3. Ignoring How It Will Be Assembled

“We’ll figure it out after printing.”

Nope. Prototypes fall apart when assembly is treated as an afterthought.

What goes wrong:

- Fasteners can’t be accessed

- Modules don’t connect cleanly

- You break parts trying to put them together

Better move:

Design for assembly from day one — even if it’s just a temporary one. Think modular, tool-accessible, and field-repairable.

4. Not Planning for Iteration

“We’ll just build one, and that’s it.”

Never. That one will almost always need changes. Plan for v1.1 and v1.2.

What goes wrong:

- No room to tweak or upgrade

- Everything is glued or permanently fixed

- No documentation of changes

Better move:

Use quick-connects, label everything, save multiple CAD versions, and always test in the wild.

How We Avoid These Traps at DzinePlus

At DzinePlus, we don’t chase perfection — we chase validation.

- We start with what’s good enough to learn

- We prioritize functional proofs over flashy builds

- We design for flexibility, fast changes, and small-batch builds

- And we respect the budget and timeline like it’s our own

Want to build something that works fast? Let’s talk.