If you design products or manufacturing processes, you already fight errors every day. Poka-yoke, a Japanese term for mistake-proofing, turns that fight into a design habit. Instead of relying on training and inspection, you shape parts, interfaces, and workflows so the wrong action simply cannot happen. The result is fewer defects, faster assembly, and less cognitive load for operators and users.

This guide explains poka-yoke types, shows practical examples at part and system level, and closes with manufacturability notes you can apply on your next drawing release.

Why mistake-proofing beats error catching

Quality systems often depend on detection, for example end-of-line tests or final inspection. Detection finds problems after time and material are already sunk. Poka-yoke prevents the error at source. Prevention is cheaper than detection, cheaper than correction, and dramatically faster to scale. It also levels performance across skill levels, which matters when teams change or products ramp.

Three core strategies

1) Elimination by design

Make the incorrect action impossible. Common methods:

- Geometry keying. Asymmetric tabs, chamfers, pin-in-slot patterns, and D-shaped holes prevent 180° or 90° misassembly.

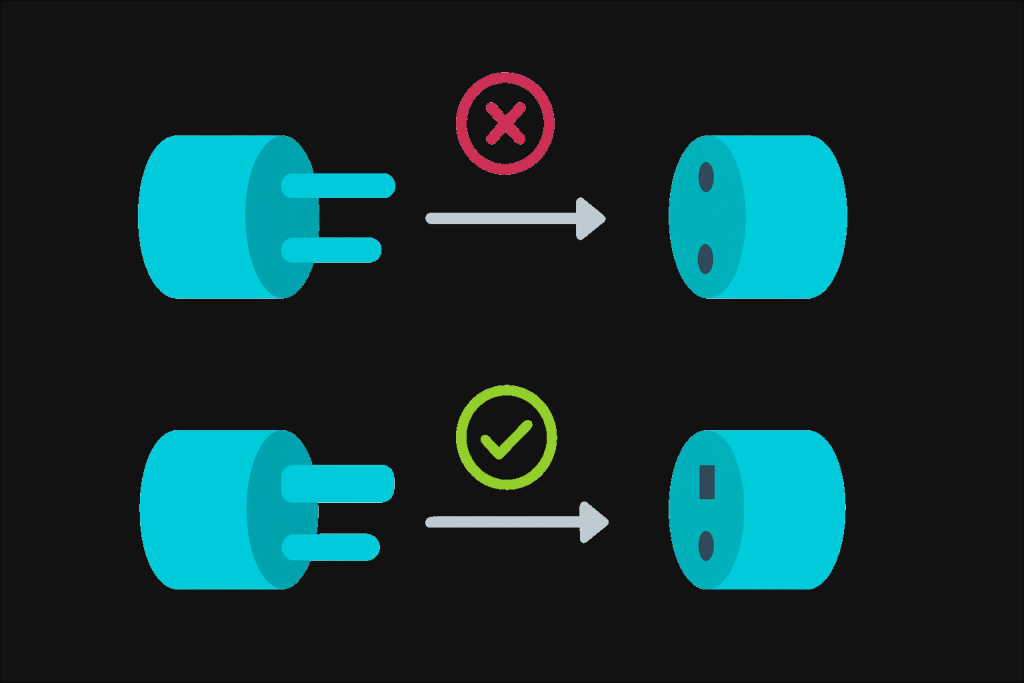

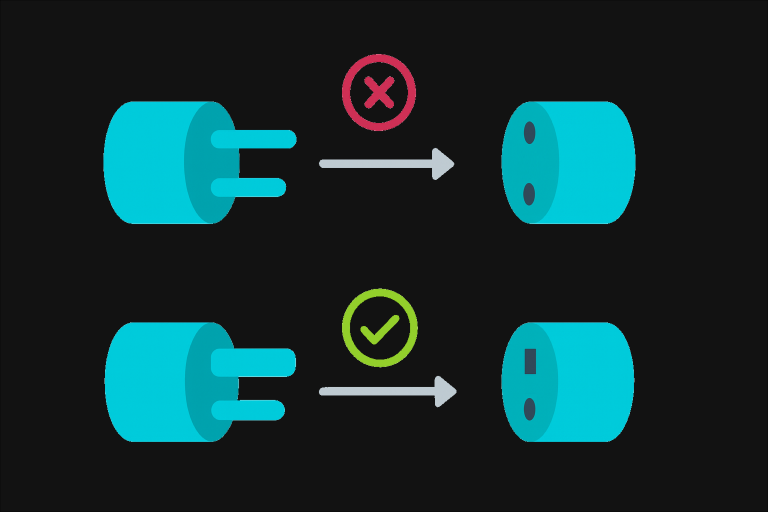

- Connector coding. Different pitch, key rib locations, or pin counts ensure only the correct cable mates.

- Fastener control. Captive screws, thread-forming in plastic, and one-way snap features remove loose hardware and tool mixups.

2) Replacement with guides and limits

If elimination is not feasible, guide the user to the correct action and limit the rest.

- Hard stops. Built-in end stops constrain travel so over-rotation or over-stroke cannot occur.

- Go/No-Go features. Gages, templates, or tapered pilots that only accept in-spec parts.

- Color and texture coding. High-contrast cues and tactile indexing help in low light and noisy lines.

3) Early detection with immediate feedback

Detect errors at the step where they occur, then block progress until corrected.

- Interlocks. A press cannot cycle until guards are closed and both palm buttons are actuated.

- Sensors. Reed or photoelectric sensors confirm a part is present before the robot moves on.

- Checklists in software. UI flow that requires a scan or torque acknowledgement before saving.

Classic examples you can adapt today

- Asymmetric bosses for PCBs. Stagger three nylon bosses, two round and one D-shaped. The board only drops in one orientation. This removes silkscreen reliance and prevents upside-down assembly.

- Quarter-turn battery doors. A cam profile that binds if the battery polarity is reversed, combined with spring geometry that only seats with the correct terminal shape.

- Foolproof fluid ports. Female Luer lock for water, barbed 6 mm for air, keyed CPC for chemicals. Each diameter and key prevents cross-connection.

- Torque control. Shoulder screws or metal standoffs set clamp load by stack height, so operators can run to contact instead of chasing torque values in soft materials.

- Packaging nests. Vacuum-formed trays with one asymmetric pocket prevent count errors and protect delicate finishes.

Designing poka yoke into parts

Materials

Choose materials that support the geometry you need for keying and snaps.

- Thermoplastics. ABS, PC, and nylon handle living hinges, snaps, and compliant guides. Aim for radii ≥ 0.5 mm to avoid stress risers.

- Sheet metal. Tabs, lances, and embossed features can create indexed assembly without added parts. Maintain bend radii ≥ material thickness.

- Castings and MIM. Complex keying features form easily. Add draft 1 to 2 degrees, keep minimum wall 2.5 to 3 mm for aluminum die cast.

Tolerances

Poka-yoke relies on clear fit hierarchy.

- Use clearance for guidance. Pilot features should lead, functional datums should lock. Apply tighter tolerances to pilots and locks, looser to cosmetic shells.

- Plan stack-ups. If an interlock must engage, set datum references to guarantee overlap under worst case. Run a simple 2D stack and check ±3σ if you have process data.

- Define gage limits. For Go/No-Go pins, specify sizes in metric with class fits, for example 6 H7 hole with a 6 g6 gage pin.

Surface finishes

Finishes change friction and readability.

- Molded textures. Light textures mask scuffs and improve grip for alignment, for example VDI 12 to 24.

- Anodized aluminum. Hardcoat lowers galling risk on sliding keys. Call out sealing when used near corrosives.

- Color coding. Use molded-in color or laser marks where solvents or abrasion are present, avoid stickers in washdown.

Common failure modes to anticipate

- Tolerance collapse. Keys intended to block rotation may wear in soft plastics. Add bosses with steel inserts or increase bearing length.

- Ambiguous cues. If a part looks symmetric, operators will treat it as symmetric. Break symmetry visibly, for example one corner radius twice the others.

- Defeatable interlocks. If a machine must be bypassed for setup, add a dedicated setup mode with reduced speed and hold-to-run, not a tape-over workaround.

Design for assembly tips

- Reduce options. Standardize fasteners to two sizes, or replace them with snaps. Fewer choices mean fewer chances to choose poorly.

- Keep hands free. Use self-retaining features so one hand can hold the tool. Dovetails, light press fits, and magnets help.

- One-way flow. Design stations so parts can only move forward. Gravity chutes, left-to-right fixtures, and error-proof kitting reduce backtracking.

Applying poka-yoke in software and mechatronics

Physical and digital systems share the same logic. In embedded products, combine mechanical keying with firmware checks. For example, a keyed cartridge pairs with an EEPROM that reports batch ID. The controller verifies ID and expiration before enabling pumps. In consumer apps, constrain input formats, for example mask phone numbers and prevent submit until checks pass. The point is the same, prevent invalid states, then guide recovery with clear prompts.

Economic impact and metrics

Poka-yoke returns show up in first pass yield, rework minutes, and warranty claims. Track three metrics per change:

- Defect opportunity count per unit, for example number of connectors that can be cross-mated.

- Defect rate before and after, parts per million or percent.

- Time to detect from occurrence to discovery. Aim to push detection to zero by eliminating the error.

Simple changes like adding a D-flat can remove whole inspection steps and minutes per unit. Over a year, that is real money.

Getting started checklist

- Map your top three defects by frequency times severity.

- Sketch one physical or software barrier per defect that prevents the cause.

- Prototype with foam, 3D prints, or temporary guides in less than one week.

- Validate in a short pilot, measure before and after.

- Lock successful features into drawings and work instructions.

Small, irreversible steps build a robust system that resists drift and turnover.

Glossary

Poka-yoke

Mistake-proofing design that prevents incorrect actions or detects them immediately.

Go/No-Go gage

A simple tool with pass and fail limits that quickly checks a dimension without reading a value.

Interlock

A mechanism or control logic that blocks dangerous or incorrect actions until conditions are safe.

Keying feature

Geometry that forces one orientation or one mating combination.

First pass yield

Percentage of units that meet all requirements without rework.

Learn More about Poka-Yoke Design

Have an idea ? Lets talk Contact Us