Bringing a product idea to life isn’t just for tech giants with huge budgets. Whether you’re a solo founder, a small team, or just someone with a vision and a sketch on a napkin, the path from concept to physical prototype is now faster, smarter, and more accessible than ever.

Here’s a real-world, startup-friendly guide to help you make it happen, step by step.

Step 1: Clarify the Problem, Not Just the Product

Before designing anything, get clear on what problem you’re solving. Is it convenient? Cost? Sustainability? Cool factor? That clarity will drive every decision you make next.

If you can’t explain the value of your idea in one sentence, you’re not ready to build it yet.

Step 2: Sketch What You Think You Want

No fancy tools are needed – napkin doodles count. Start sketching the physical form, how someone would use it, where the buttons go, and how it might feel. You’re building a vision, not a final product.

Want to level up? Use Figma, Fusion 360, or just take a photo and annotate it.

Step 3: Make a Digital Model

Now it’s time to translate your sketches into something buildable.

This is where CAD (Computer-Aided Design) comes in – tools like SolidWorks or Fusion 360 turn your idea into a 3D model, allowing for testing, measuring, and realistic renders.

Don’t know CAD? That’s what teams like Dzine⁺ are for – we model, stress-test, and iterate fast.

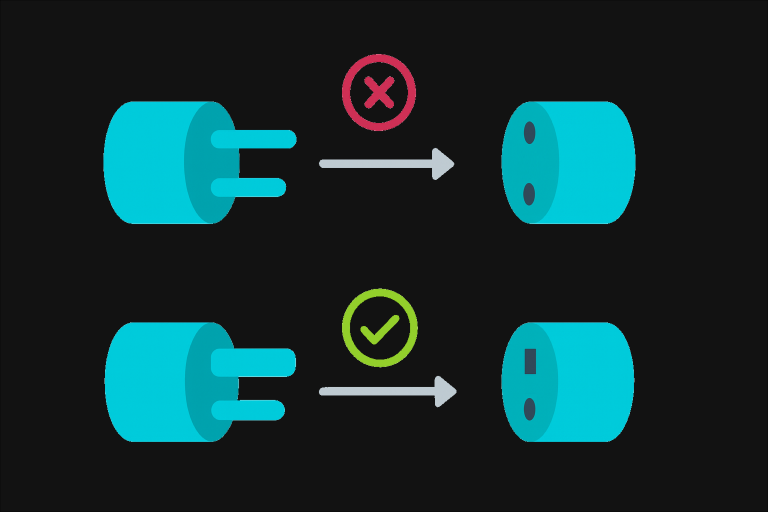

Step 4: Choose the Right Prototyping Approach

Every idea has a different “best first step.”

- 3D printing → perfect for form + fit

- CNC machining → great for precision parts

- Laser cutting → useful for panels, enclosures, or quick iterations

- Electronics breadboarding → ideal for functional proof of concept

Choosing the wrong method = wasted time. The right one = momentum.

Step 5: Build. Break. Repeat.

Your prototype won’t be perfect. That’s the point.

You want to test the idea — does it feel right in your hand? Do users get confused? Are your assumptions correct?

This is where the magic happens. You iterate fast, fix what’s broken, and move forward smarter.

Working with Dzine⁺ means you’re not alone in that loop — we’re your technical co-founder when it comes to prototyping.

Step 6: Prepare for Manufacturing

Once the prototype is solid, we help you take it further, optimizing it for real-world production, materials, suppliers, and cost efficiency.

You’ll walk away with:

- Design files that manufacturers can use

- A physical model you can show investors

- Confidence to pitch, test, or launch

Final Thoughts

Ideas are easy. Execution is everything.

If you’re serious about turning that idea in your head into something real-something physical you can touch, test, and show, prototyping is your first real step forward.